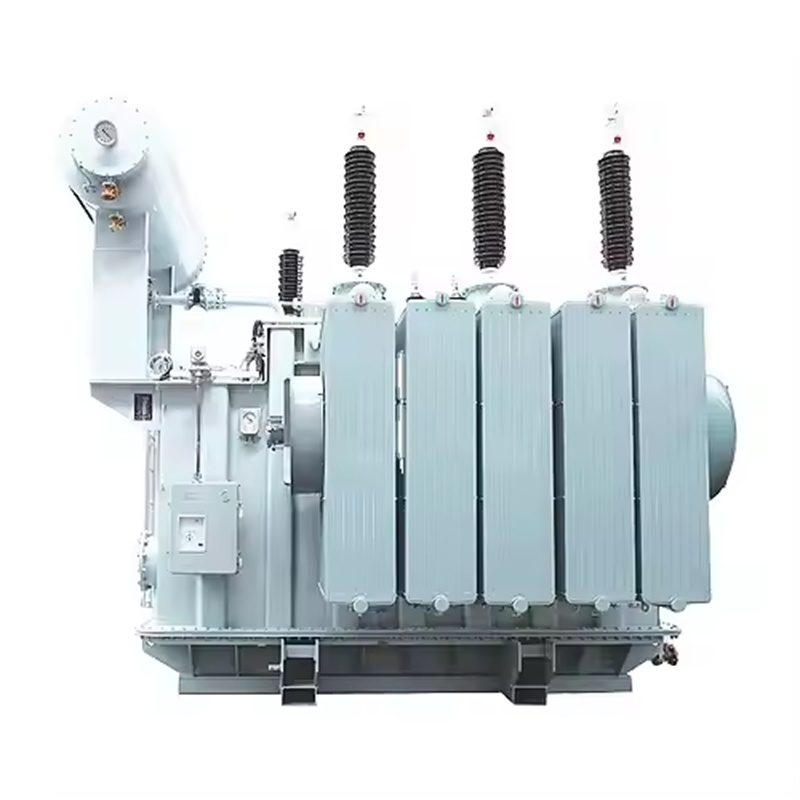

Industrial electrolysis is important to a number of different industries, from metal smelting to water treatment. A stable and dependable power supply is irreplaceable in electrolysis work to keep the procedures running efficiently and effectively. And that’s where rectifier transfromers are used. A rectifier transformer is such that an electrical transformer for industrial applications where the alternating current (AC) is converted to direct current (DC). Rectifier equipment supplies a uniform and controlled DC power, conductors thus protecting the apparatus while providing a reliable source of electricity to operate electrogas processes.

Function To keep the required voltage accurately for best performance of electrolysis by rectifier transformers.

In industrial electrolysis reliability of the rectifier transformers is paramount because they are not only used to generate electricity but also for voltage regulation. The electrolysis equipment need a specific voltage for driving the chemical reactions in such a way that the desired results can be achieved. Variations or irregularities in voltage can effect on the quality and efficiency of an electrolysis process. Rectifer transformers ensure that the output voltage is kept stable and in prescribed limits achieving peak performance and productivity demand for industrial electrolysis.

How Does The Rectifier Transformer Save Electricity & Operating Costs When Electrolysis?

Contemporary rectifier transformers are efficient and deliver a stable power supply, while maintaining accurate voltage levels, with the added benefit of consuming lower energy and subsequent costs in electrolysis operations. Rectifier transformer are able to change AC voltage into DC voltage with less loss, and reduce energy consumption and the potential waste of energy while electrolyzing. This saves industrial sites money and also makes them more sustainable and environmentally friendly by decreasing total energy use.

The response of rectifier transformers to improving production efficiency and increasing capacity in industrial electrolysis.

Productivity and efficiency are critical for the competitiveness in industrial electrolysis. Rectifier transformers are the key to improved production/efficiency and output quality in many industries. As the oilfield clean water supply system is able to maintain a very stable voltage level and Power Transformer requires less energy consumption, therefore during the process of electrolysis, it can operate in a smooth manner, having an enhanced effect with more output and higher overall efficiency. And this is what allows factories to generate output, satisfy the market and be competitive.

The significance of rectifier transformers used in order to guarantee a safe and reliable electrolysis for industrial purposes

Safety is a top priority in industrial processes, and even more so for processes like electrolysis that use high voltages and complicated chemical reactions. Rectifier transformers are important to the safe & reliable electrolysis process in that they provide a regulated power supply. Rectifier transformers contribute to safe operation, reduced equipment malfunction rates and workplace safety by providing stable voltage output, lower energy consumption and higher 35kV power transformer production efficiency. Not only does this safeguard the health & safety of workers and buildings but it also meets industry requirements for the prevention of accidents, incidents or near misses.

rectifier transformer is the key equipment for the power supply of industrial electrolytic process, and its stable reliability can be guaranteed to prevent voltage fluctuation too much, save energy consumption and reduce operation cost of production line, improve production efficiency and increase output by introducing new technology. Introduction Over 30 Years of Experience Jiangsu Dingxin Electric Co, Ltd is a reliable manufacturer specializing in the changing and designing of quality rectifier transformers as well as other 110-220kV power transformer electrical products that meet the requirements of power grids, industries and world markets. Through an unwavering pursuit of excellence, innovation and the best customer experience, Dingxin Electric is shaping the future of industrial manufacturing and leading transformation across all segments of electrolysis applications around the world.